Renewable Energy

Onshore Fields

Our Green Seal Technology can build or rebuild a mechanical horse with zero carbon emissions and having a smart sensor that moves the machine accordingly to oil field levels, saving also energy and maximizing exploration.

Our PLC sends daily reports of production to the owners and/or operators of the field.

Owner of fields can claim for tax reduction or compensation using our zero-carbon emissions technology and product.

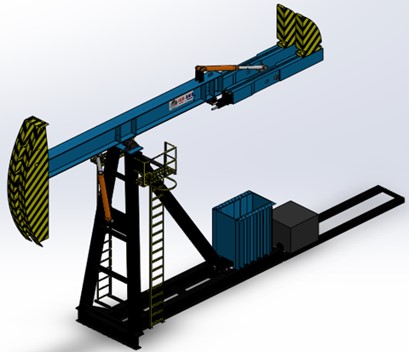

Dynamic Counterweight Pumping Unit (DCPU)

The main benefit of the DCPU (our green seal unit) is its use of hydraulic cylinders and pumps, which take away the need to utilize the reduction box and gears.

The reduction box alone is responsible for 50% of a conventional pump jacks cost.

Thus, the DCPU is less costly to produce, and the maintenance is simpler and less expensive as well.

For the reduction box is very costly part to repair.

The maintenance of the DCPU is (only if needed) directed to the bearings and the hydraulic system.

The DCPU Works utilizing motors of 30 cv max. The small amount of energy needed makes it possible to install our Renewable gravitational hydraulic generator to work alongside the pumpjack.

At the startup of the unit, the motor is required to its full potential. After that the movement requires a lot less energy due to the simplified hydraulic system and the pendulum counterweight.

A conventional unit wastes energy due to the transmission that occurs through the reduction box and belts, on top of gas carbon emissions, not present in our DCPU.

Because of its simplified hydraulic system and steel profile, the DCPU is simpler to build.

The absence of moving parts such as the reduction box, cranks, connecting rods, belts and pulleys make the DCPU’s maintenance simpler and way less expensive than a traditional unit.

The Software

The DCPU utilizes a software control technology called PLC.

The PLC can control the cycles per minute with the varying speeds from 0.5 to 18 cpm.

The software also allows the precise control of actuation time, making it suited to wells with viscous oils.

By controlling the cycles per minute, it is possible to reduce the percentage of BSW (% of water in the fluid), increasing the well’s productivity.

Temperature control flexible resistance (REFLECONT)

RPS Energy Presents an innovating project to help control temperature at Oil facilities named “Temperature Control Flexible Resistance (Reflecont)”.

“Reflecont” was developed to be used in subsurface and surface facilities where paraffin wax fluids flow, bringing great efficiency when utilized in wells. the maintenance and maintenance increase in the column will influence the productivity index of the well, as the rise in temperature will reduce the oil’s viscosity, then the liquid phase turns to gaseous, reducing the flux pressure. In short, for the same number of static pressure (PE), a production with a smaller load loss will allow a lower flux pressure (Pf) with significant gains in production.

– Surgency wells.

The technology can be introduced directly in the interior of the column of surgency wells without any loss in production. The depth of the resistance far end is determined by the dynamic temperature record.

– Pumped wells.

For pumped wells (BM, BCP, BCS, etc.), the resistance can be introduced at the ring space. In this case, the use of a shudder at the bottom of the well is recommended (above the perforation) as is the presence “packer fluid” in the ring space.

The head spread will occur in the interior of the column. Depending on the situation, a bundle of surface equipment, those used for water catchment (BCS Christmas tree plus T-16-F 2.7/8” suspensor for 2/4AWG cable plus T- 16 7” production head), can be adapted for:

BCS elevation wells the following equipment can be utilized: 2.9/16” x 5000 psi crosshead Christmas tree + 7.1/16” – 2.9/16 x 5000 psi AEC adapter with electrosub mandrel + TC-00 11” – 7.1/16” x 5000 psi production head and TC-BEC 6” x 2.7/8” EU sus

* Advantages

The confirmed benefits of the technology will be listed in its utilization at gas lift wells, and possible benefits, yet to be tested, in other applications.

– Gas lift wells

· Real 12% production gain;

· Temperature control inside the well;

· Cessation of paraffin wax buildup;

· Oil viscosity reduction;

· Load loss reduction at the ascending flux;

· Higher gasification in the column;

· Flux pressure reduction at the bottom (Pf);

· Higher productivity index (IP);

· Cost reduction with less pig utilization at the surgency line;

· Cost reduction with the end of any wire clearing of the paraffin wax (UDMS)

· Cost reduction with the end of the heated fluid circulation operation (UCOQ);

And much more. Contact us for more details

Gravity Energy Generator (MGH8)

The GRAVITY ENERGY GENERATOR Unit performs movement through force conservation by means of a pendulum, and two-cylinder hydraulic assist.

•The MGH8 GENERATOR uses a dynamic counterweight whose displacement / linear forces the synchronous movement with the head of the mechanical unit, having as element associated with the force of gravity and a rotating hydraulic pump.

Zero Carbon Emission, 95-97% Energy Efficiency.

WITHOUT FLOODING OF FUELS OR GAS, WITHOUT FLOODING OF WASTES OF ANY SPECIES THAT POLISHES THE ENVIRONMENT AND ISSUES HEAT TO THE ATMOSPHERE, WITHOUT AIRCRAFT NEEDS, WITHOUT SUN OR WIND NEED.

Contact us for more details.